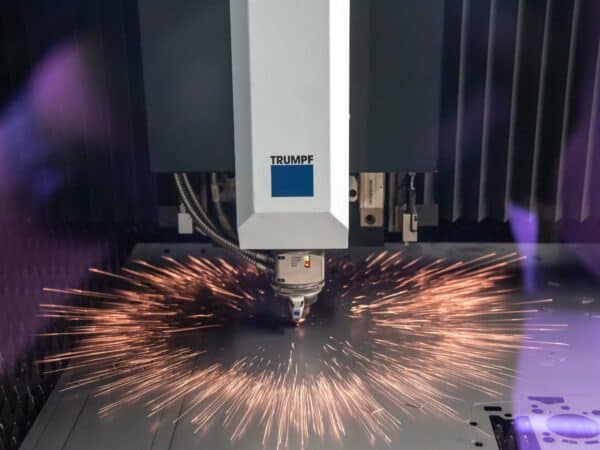

The pressure on industry is growing: Politicians and the public are pushing for greater sustainability, while at the same time digitization is driving the cycle of innovation ever faster. Dr. Thomas Schneider, Managing Director of Development at TRUMPF Machine Tools in Ditzingen, Germany, explains in an interview how mechanical engineering supports the transition to a circular economy and the establishment of a green factory, and how business models are changing.

An interview with Dr.-Ing. Thomas Schneider, Managing Director Development, TRUMPF Machine Tools

Dr.-Ing. Thomas Schneider is Managing Director of Development at TRUMPF Machine Tools in Ditzingen. After completing his studies in mechanical engineering with a doctorate at the Karlsruhe Institute of Technology (KIT), he took on various positions in development and, among other things, headed the development of flight control and actuation systems at a family-owned company. In 2016, he joined TRUMPF as Head of Production Platforms and has been responsible for development in the Machine Tool Business Division since the beginning of 2018.

Dr. Schneider, at TRUMPF, agile teams of mechatronics engineers, computer scientists and mechanical engineering experts develop innovative products. How does one go about executing a successful link to the topics of sustainability and climate protection? Do you also integrate sustainability experts into the individual development teams?

We are a technology push company, and as such, are actively driving change. This includes the topics of sustainability and climate protection. As a major strategic initiative of the TRUMPF Group, these areas are anchored in all parts of the company. Specifically geared towards development, our teams consist of three groups: product management, R&D and value stream. Within Product Management lies the responsibility to consolidate sustainability issues and bring about decisions. The topic of sustainability is thus brought into the development teams via Product Management. As an innovator, we stand by our convictions and supply the market with increasingly more sustainable products. But our customers also challenge us. Catchphrase Green Factory. We share a symbiotic relationship with our customers, working together with them to meet global challenges.

Are there conflicting goals within the development teams because the best technical solution has to be combined with sustainability criteria? And do these slow down or spur on the inventive spirit?

There is no barrier to implementing the optimal solution, because more sustainable products make a positive contribution to all of us and the next generation. And: At TRUMPF, we couple sustainability with digitalization. The aim is to tackle issues of sustainability in a measurable, quantifiable and data-based manner. In this way, we want to better understand the achievable contribution of sustainability in order to make the right decisions. This systemic approach has a stimulating effect on inventiveness.

What other options are available to TRUMPF in terms of environmental and climate protection?

With the EUV lithography for high-performance chips we’ve developed at Zeiss and ASML, we are helping to ensure that smartphones or computers operate much more efficiently and in a more climate-friendly manner. In this market of the future, we are the only laser manufacturer in the world who can do this. We also set high targets for ourselves, retrofit buildings and optimize production. This is one of the reasons why the TRUMPF Group is already CO2-neutral in terms of its balance sheet. We − and our owners as the primary drivers − are highly motivated to achieve the 1.5-degree target. Our greatest leverage though is our customers. We support the transition to green factories and holistic business models. If we are successful with this, so are our customers.

About the company

The TRUMPF Group, headquartered in Ditzingen near Stuttgart, Germany, is one of the world’s largest suppliers of machine tools and is represented in all major markets worldwide by more than 70 subsidiaries. In the 2020/21 fiscal year, the company generated sales of more than €3.5 billion with almost 15,000 employees. Originally founded as a mechanical workshop in 1923, TRUMPF has today become a market and technology leader in machine tools and lasers for industrial manufacturing. Thanks to innovative software solutions, the company is also considered a partner on the road to the smart factory.

More about sustainability in mechanical and plant engineering

Sustainability

The manufacturing industry has a responsibility to reduce its environmental footprint. Legal requirements and growing social pressure have set a process of rethinking in motion: corporate leaders see a need to reassess the environmental impact of their work.

Read more

“As a family-owned company, we always think and act with an eye to the next generation”

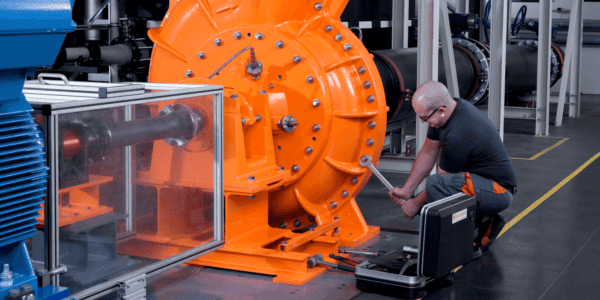

Munsch Pumpen, whose products are used especially in the chemical industry and for metallurgy, has been producing pumps since the 1960s. This company in the Westerwald is currently managed by Stefan Munsch, the family’s second generation. In the interview, this graduated engineer explains why sustainability was always writ large at Munsch and why he would sometimes like lawmakers to be a bit more practical.

Read more

Study Green Transformation 2022

On a total of 56 pages, the study provides a detailed insight into this industry’s sustainability strategy. In addition, we compare the results with important findings from the study “Green Transformation in the Automotive Industry” conducted last year. Expert reports from Munsch Chemie-Pumpen GmbH and TRUMPF Machine Tools offer exciting impulses directly from the field….

Read more