How do you quantify causalities in your supply chains?

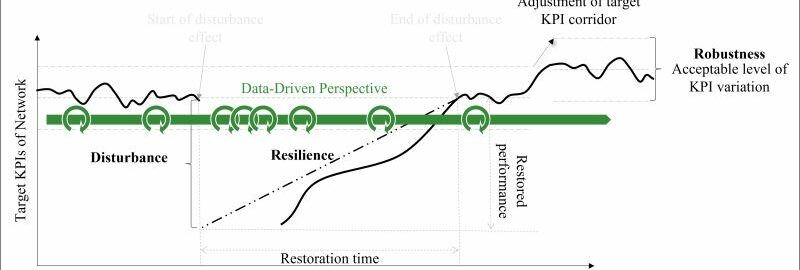

The Supply Chain Triple R (Robustness, Resilience, Responsiveness) depends on the global production network and its causal chains. The correct quantification of these dependencies is the most important basis and also the holy grail for risk assessment. In a data-driven view of supply chains, the right key figures are required for this purpose.

In their development, the following three elements should be considered:

- ValueAdded, which the additional quantification provides for the risk consideration

- Understanding what part of reality the metrics do not represent

- The right aggregation levels and time horizons

Right balance between accuracy and speed in data collection

The production network with globally distributed locations, a heterogeneous system landscape and complex material structures poses challenges for data collection. An inventory of the necessary and existing data as well as their quality is the start. The collection of new data, e.g. on demand, inventories, deliveries, complaints or external market events, requires a well thought-out and structured procedure. Data collection, preparation and consolidation requires a digitally automated and efficient approach. Depending on disturbance and the restoration time, the rolling collection is carried out with an adapted horizon and frequency. An optimal balance must be found between accuracy and speed depending on the situation.

Interested?

If you are interested in the current status of the Triple R Innosuisse project, please contact us.

We would be happy to show you how corporations or SMEs pragmatically assess their supply chain risks and configure the production network accordingly.