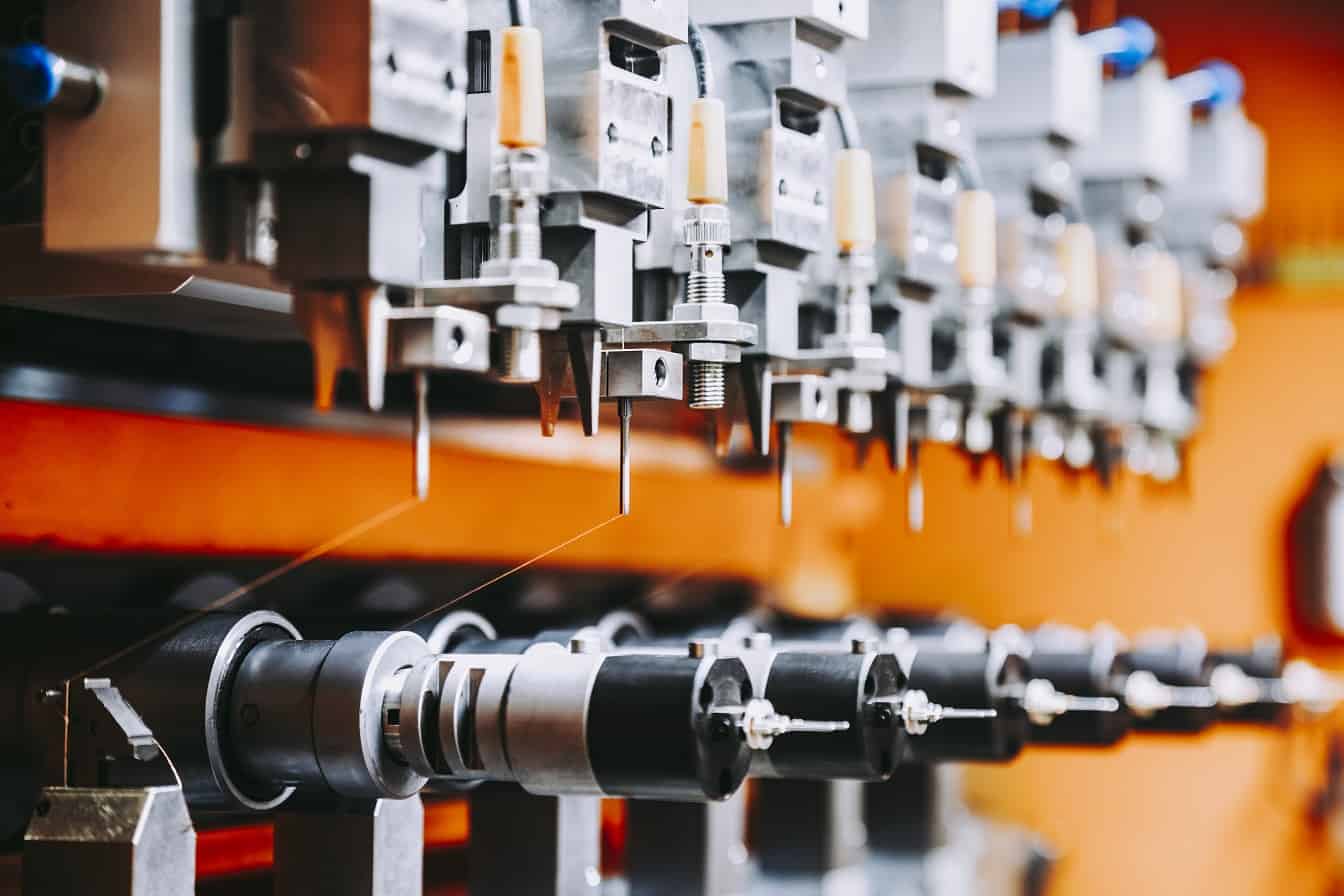

As one of the leading providers of innovative automation technology, ifm has been setting the standard in matters of digitalization for years. With a highly modern green factory in Sibiu, Romania, the sensor technology specialist has now also placed itself in the pole position with regard to sustainability.

If you build a factory on an empty plot, you can do a lot of things correctly from the very beginning. An example of this is the ifm group, which primarily provides sensors for industrial applications. In addition to the central office in Essen, Germany, and the development and production in Tettnang on Lake Constance, the group has numerous locations abroad. One of these is Sibiu in Romania, where position and pressure sensors are manufactured. When it became obvious a few years ago that the production capacities there would soon reach their limits, ifm decided to build a new factory in the immediate vicinity. And this wasn’t to be just any factory, but rather a true green factory.

“The company management wants to leave a sustainable footprint for coming generations and was prepared to bear the additional expenses compared to a conventional factory, which amounted to around €3 million for a CO2 neutral factory,” says Bernd Hausler, Managing Director at ifm. The attractiveness of the site is one reason for investing this money in Romania. “So far, we have never had any problems attracting a sufficient number of skilled workers for the factory in Sibiu. The illness rate is low, as are wage costs in comparison to other European countries,” says Alex Magdoiu, executive director of ifm in Romania. “In addition, many companies are currently moving to Eastern Europe and especially to Romania.”

Central logistics center in the heart of the cloverleaf

There was intense planning before the excavators broke ground on the 13,000 m² construction site in March 2022. It was important to the responsible parties that the new factory have a flexible design, so that the broadest possible spectrum of ifm products could be manufactured there in the future. This was accomplished by means of the so-called cloverleaf principle, in which a logistics center is located at the center of the factory site, from which all of the production halls located around it can be supplied directly.

The German Sustainable Building Council (DGNB) was on board from the beginning. Among other things, they ensured that as little waste as possible was produced on the construction site, the groundwater was not contaminated, and low-emission materials like green concrete were used. Because the goal of ifm was certification in accordance with the international DGNB system. The plan was successful: as a green, CO2-neutral factory, Sibiu was awarded with a gold medal by the DGNB when it was opened in May of this year.

Presenting all consumption up to the production line in figures

Power supply plays an important role in the creation of a green factory. “As an electronics manufacturer, we must meticulously control the temperature and humidity,” explains Gerhard Deierling, both the production manager of ifm in Germany and the Executive Director of ifm in Romania. Cooling, in particular, requires a lot of energy. For that reason, the basic temperature of the production area is controlled via an active foundation in the new factory. The necessary heating or cooling is therefore carried out efficiently via an appropriate ventilation system.

A photovoltaic system on the roof, heat pumps, and a modern gas system, which can be upgraded with new technologies, round out the energy concept. Due to the steep increase in energy costs, the additional investments will pay for themselves quickly, Bernd Hausler is certain. “After we have created the basis for green production with this, we plan on additional expansion levels in the future,” Gerhard Deierling adds. “For example, we want to measure the consumption of compressed air, cooling volume, and power up to the production line and present these in figures. Then, we can constantly work on optimization and give every product a stamp stating how much energy went into its manufacture.”

Climate-neutral operation by 2030

ifm is using its extensive digital expertise to reach its sustainability goals by digitalizing building management and production – and not only in Romania, but throughout the entire group. Alex Magdoiu is proud of what has been achieved in Sibiu. “If we here in Romania have profited greatly from the experience of our German colleagues, we can now provide a great deal of knowledge on the topic of sustainability on our end.” His colleague Bernd Hausler stresses, “The customers expect us to provide a roadmap to decarbonization in manufacturing. It is therefore our goal to have climate-neutral operation by 2030.”

In addition to ifm customers, other companies will also be able to see what is currently state-of-the-art in green factories. Because, as a BestPractice Partner of Staufen AG, ifm will soon open its factory doors in Sibiu to interested parties. “When it comes to the triad of lean, digital, and green, there are few companies that have made as much progress as ifm. And regardless of whether we support ifm with lean management in Romania or within the scope of the digitalization project in Tettnang, we learn something each time,” says Staufen consultant Dr. Werner Laub, who has assisted the development of ifm for many years. ifm manager Bernd Hausler expresses it like this: “Constant exchange and the establishment of a good network are very important for securing one’s own competitiveness.”

Involved persons

Bernd Hausler

General Manager

ifm efector gmbh

Dr. Alex Magdoiu

Managing Director

ifm efector s.r.l. ifm prover s.r.l.

Gerhard Deierling

Managing Director

ifm prover s.r.l.

The Company

The ifm group develops, produces, and sells sensors, control systems, and software & systems for industrial automation. Its products and services are marketed in 165 countries. Essen is the main headquarters of the family-owned group. The main site for development of production is Tettnang. The company has further production sites abroad and most recently had a turnover of more than €1.4 billion with around 8750 employees.

1,4

billion € turnover

8.750

employees

165

Countries to which distribution takes place

Request the Magazine now as a digital or print version

You might also be interested in

From cost factor to competitive advantage

Many companies have seen legal requirements such as the EU directive on sustainability reporting primarily as a cost-intensive burden. Axel Banoth from Fokus Zukunft and our partner Peter Trick propose a change of perspective.

Read more

“Lean, digitalization and sustainability will be even more tightly interwoven.”

ifm is a leading supplier of innovative automation technology. Managing Director Bernd Hausler explains in an interview how digitalization is helping open up new fields of business and what challenges the industry will struggle with in the future.

Read more

Go Green – an opportunity for long-term competitiveness

Heat records, forest fires, dried-up rivers and lakes – climate change caused by greenhouse gas (GHG) emissions can no longer be ignored. In Germany, industry is responsible for around one-fifth of GHG emissions.

Read more