Reduce costs, produce sustainably, strengthen competitiveNess

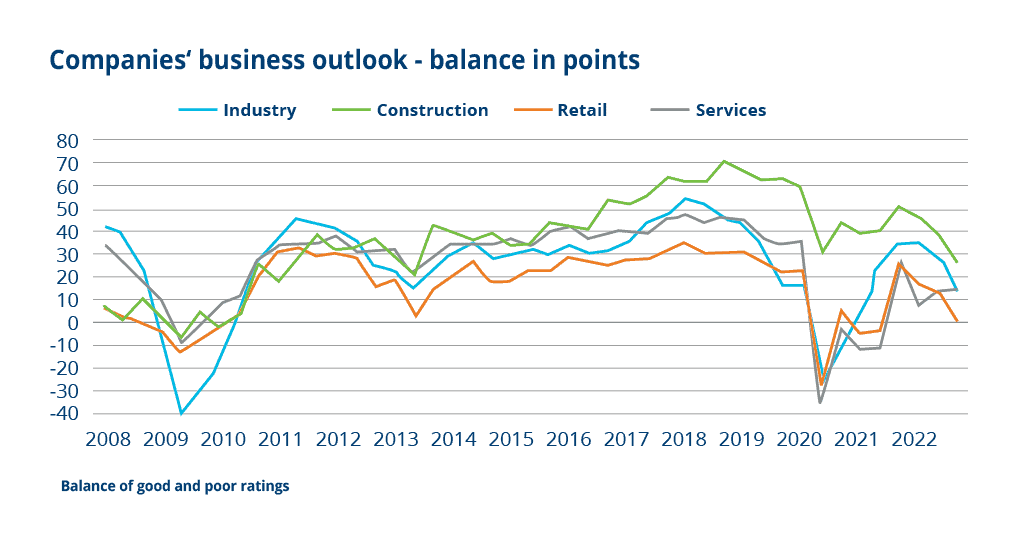

We are in the midst of a recession. German industry is currently facing difficult months ahead. Increasing energy costs and sharply increased prices for raw materials and pre-products ensure significant burdens, especially in industry. Added to this are interruptions in supply chains and an ever-more-dramatic lack of skilled workers.

54 %* of industrial companies believe that business will get worse in the next 12 months.

Depending on the industry, the dim outlook and cost pressures are significantly affecting companies’ balance sheets. More and more companies are gnawing away at their equity capital; others are already experiencing liquidity bottlenecks.

But in this tense financial situation, how can companies reduce their costs without robbing themselves of future prospects?

Staufen’s approach ensures that companies will remain competitive in the long run

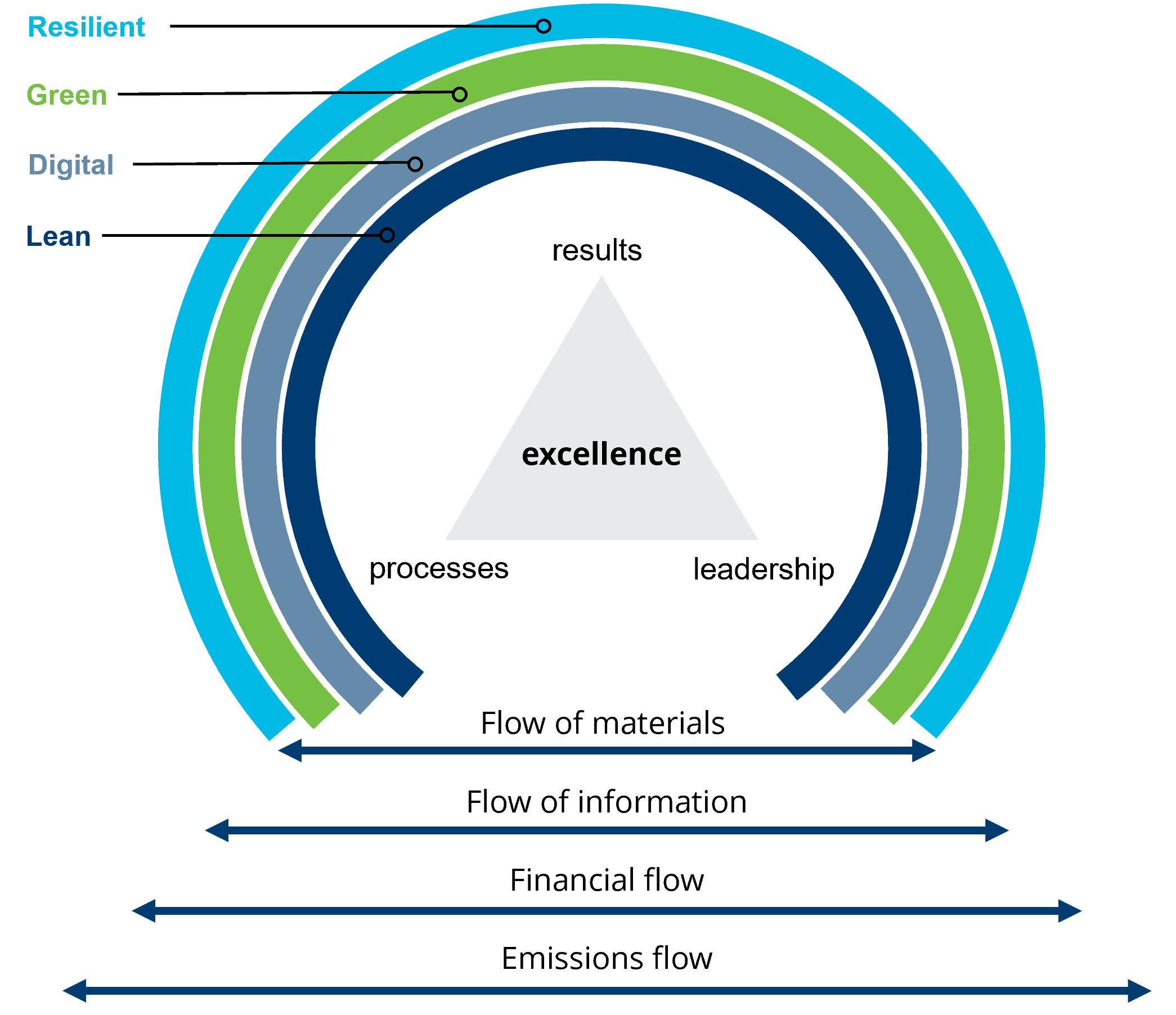

Just wielding the red pen and ensuring savings in the short term is not enough to improve results in the long run given the many-layered nature of current challenges. That’s why Staufen has developed a comprehensive approach that includes the dimensions Lean, Digital, Green, and Resilient that ensures companies’ long-term competitiveness.

Lean

Lean as the basis of customer-centered end-to-end process design with the goal of reducing waste and lead time

Digital

Digital applications and process-supporting technologies create new space to increase performance and efficiency

Green

Design of environmentally-neutral product life cycles and resource-conserving processes are core elements of future companies

Resilient

Design of company-wide adaptability provides the answer to the intensity and dynamics of changing market and environmental conditions

Important is that companies put themselves in a position to react to new challenges quickly and efficiently and make forward-looking decisions.

Christian Möllers

Partner, Staufen.Ag

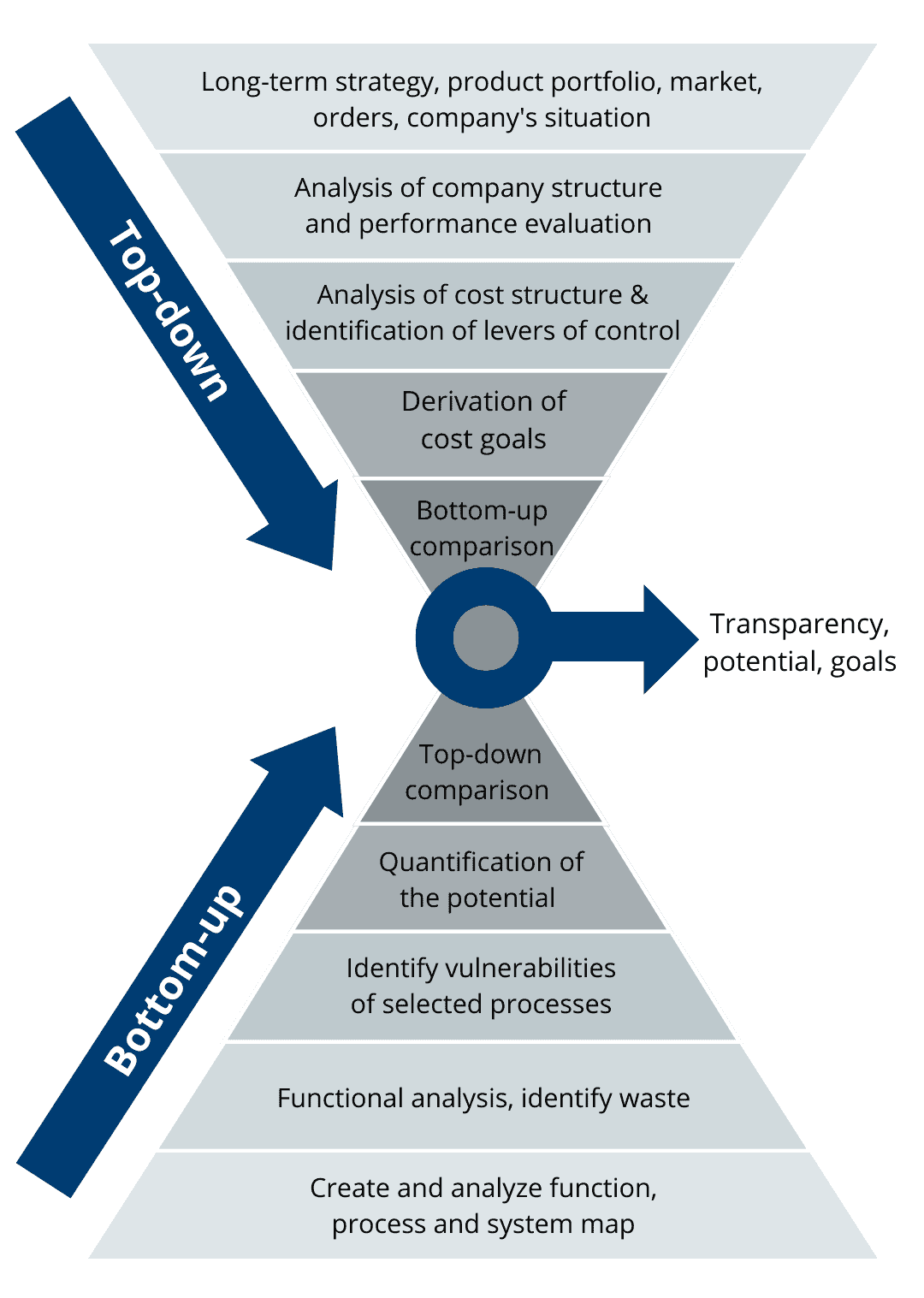

Fundamental for continuous improvement: an integrated Top-down/Bottom-up approach

Where support begins and how extensive it is depends on the individual customer. The maturity level of the individual company plays an important role here, as do the specific challenges and improvement potential identified.

When searching for cost and effort drivers, Staufen relies on a top-down/bottom-up analysis (see graphic).

All areas of a company along the value chain, from core functions to auxiliary functions, are put on the test bench in order to identify potential savings. The goal of each measure is to increase efficiency at the company and reduce lead time. Elimination of the drivers identified is reflected directly in the profit and loss calculation and the company’s balance sheet.

However, long-term improvement of company performance is not achieved solely by optimizing processes, but also by anchoring lean and change expertise in leaders and the team.

SUCCESS STORIES FROM SATISFIED CUSTOMERS

Meanwhile, this approach has proven itself in numerous successfully-completed projects, among others at the agricultural machine specialist LEMKEN and its Dutch subsidiary Steketee.

The re-measurement of the world

The Mahr Group didn´t want to rely on past successes, but instead to use its strong position to rework its inventory management and product portfolio. Together with a team of consultants from Staufen AG, this manufacturer of measurement instruments in Göttingen was able to achieve its ambitious goals.

Read more

The seed has sprouted

From development to sales – agricultural technology specialist LEMKEN is facing the challenges of lean management in terms of quality, delivery reliability and costs as well as increasing complexity in processes and products. The “lemken excellence” initiative is the key to unlocking potential and empowering employees for this long-established company from alpen on the lower rhine river, germany. The close and early involvement of controlling in the project ensures company-wide acceptance, target orientation, and quantifiability.

Read more

Polished and professional

With its camera-controlled hoeing machine, the Dutch company Steketee has built a name for itself as a niche provider in agricultural weed control – and so was a perfect fit for the portfolio of the agricultural heavyweight LEMKEN. In order to meet the process standards and KPIs customary at its new German parent company as quickly as possible after the take-over, Steketee’s Managing Director, Iljan Schouten, set to work with Staufen to restructure the company. With success! And to ensure that the company can continue on its growth trajectory, Steketee will even move into a new factory in the year ahead. Goed gedaan! Well done!

Read moreWhat distinguishes our cooperation with our customers?

Initially, we leave the ‘crude’ red pen in the drawer

We focus on operative excellence and eliminating/minimizing waste. Our customer-specific analysis combines the best of the financial and function-focused worlds.

Our experts act on a level playing field

Our ranks include many specialists with long-standing industry experience; among others in the development, sales, purchasing, and operations sectors.

Our work can be measured

We identify your optimization potential and start directly by implementing so-called quick wins. For the implementation of additional measures, we pay attention not only to quality, costs, and delivery performance, but also to an adequate return on consulting. Experience has shown that one EUR of consulting work corresponds to at least three EUR improvement in results every year.

Continuous improvement after the project is over

In projects, we place great value on leadership excellence and empowering employees. This way, the path of continuous improvement can be continued seamlessly without our external consulting and the company’s value increased constantly.

Long-lasting competitiveness is not a result of extensive cost-cutting, but rather of lean, optimized processes and the continuous improvement process that they embody.

Christian Sprenger

Partner, Staufen.AG

Feel free to contact us.

Ensuring competitiveness in the long run means more than just wielding the red pen. Our team looks forward to guiding you.

Christian Sprenger

PartnerSTAUFEN.AG

After finishing his studies of business administration with focus on Corporate Finance and Management at the universities of Tübingen and Mannheim Christian Sprenger worked for the Wintergerst Societät für Unternehmer-Beratung for four years. There he accompanied various restructuring, growth and reorientation projects as well as M&A processes, primarily in the area of production companies. Christian Sprenger’s expertise especially lies within the field of Working Capital Managements as well as the analysis and development of integrated financial plans and financial modeling.

Read more

More about cost reduction

“Complexity as the main cost driver”

Dr. Christoph Weiss has formed companies from a diverse range of situations in his career: advisor, restructuring manager, corporate manger, and proprietor. As CEO of C & E Fein GmbH, he has worked with the support of Staufen AG to focus more closely on the indirect areas. In a discussion with Christian Möllers, a partner at Staufen AG, he explains how they went about raising efficiency potential there.

Read more

Price negotiations are delicate but essential.

Supplier companies are exposed to a wide range of external influences. To maintain profitability at constant selling prices is thus becoming more difficult. For this reason, it is essential to negotiate prices with customers.

Read more

Cost pressure: “Cost cutting alone is too short-sighted and certainly not sustainable!”

All signs in the German economy are pointing to recession. So where can companies start to build up more resilience despite the challenges and enormous cost pressure? What can they do to strengthen their competitive strength over the long term? Staufen experts Christian Möllers and Christian Sprenger respond to the most pressing questions.

Read more